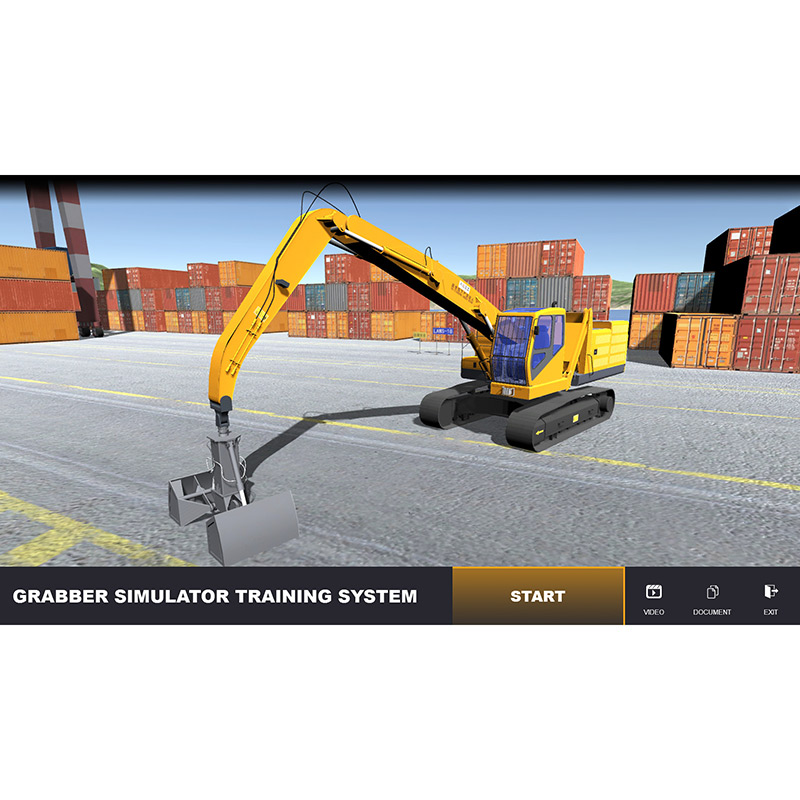

3D VR Construction Grabber Personal Training Simulator

Grabber simulator complies with the latest grabber driver training syllabus and is equipped with the latest "grabber simulation system" version.

The software model uses a grabber as the prototype to design and produce a real-scale 3D model.

During operation, the realistic three-dimensional scene corresponding to the operation is displayed on the video and accompanied by corresponding voice prompts.

The subject contains a large number of real-time error prompts, including text prompts, voice prompts, and flashing red on the screen. Help students correct illegal operations and wrong actions in a timely manner.

Features

1) Improve teaching quality

The system cooperates with sound, image, animation and interactive visual equipment to train students to master various operating skills and techniques of continuous wall grab before actual machine operation. By operating more than 20 realistic continuous wall grab training projects, the training time is extended, thereby effectively making up for the shortcomings of the real machine training time, achieving the goal of practice making perfect and improving training efficiency.

2) Cost saving

While improving the quality of teaching, the simulation training teaching instrument effectively saves the training time on the real machine. The training cost of a simulated training teaching instrument is only 1 yuan/hour, which saves huge teaching expenses for the school.

3) Enhance security

The trainees will not bring accidents and risks to the machine, themselves, or school property during the training.

4) Flexible training

Training can be carried out whether it is daytime or rainy days, and the training time can be adjusted flexibly according to the school's situation to completely solve the teaching inconvenience caused by climate problems.

5) Personalized customization

The software and hardware of the simulator can be modified and customized for a fee according to the needs of customers.

Configuration Details

High-sensitivity operation handle, foot pedal, control box, data acquisition card, computer, liquid crystal display, main control chip, membrane button, multi-function combination control button, throttle knob, auxiliary control (OK, exit), etc.

Training topics:

Empty action, hanging grab, groove grab experiment, single assessment, comprehensive assessment

Application

Grabber simulators are used for many global work machinery manufacturers to design and implement simulator solutions for their machines;

Grabber simulators offer next generation work machine training solutions for schools in the fields of excavation and logistics.

Parameter

| Display | 40 or 50-inch LCD display or customized | Working voltage | 220V±10%, 50Hz |

| Computer | Satisfy the use of software | Ambient temperature | -20℃~50℃ |

| Seat | Special for construction machinery, adjustable front and rear, adjustable backrest angle | Relative Humidity | 35%~79% |

| Control Chip | Independent research and development, high integration and high stability | Size | 1905*1100*1700mm |

| Control Assembly | Designed in accordance with ergonomic principles, easy to adjust, all switches, operating handles and pedals are within easy reach, ensuring operating comfort and greatly improving learning efficiency | Weight | Net weight 230KG |

| Appearance | Industrial appearance design, unique shape, solid and stable. The whole is made of 1.5MM cold-rolled steel plate, which is sturdy and durable | Support Language | English or customized |