Excavator is an earth-moving machine that uses a bucket to excavate materials above or below the bearing surface and load it into a transport vehicle or unload it to a stockyard.

The materials excavated by the excavator are mainly soil, coal, silt, soil and rock after pre-loose. Judging from the development of construction machinery in recent years, the development of excavators is relatively fast, and excavators have become one of the most important construction machinery in engineering construction. The three most important parameters of an excavator: operating weight (mass), engine power and bucket capacity.

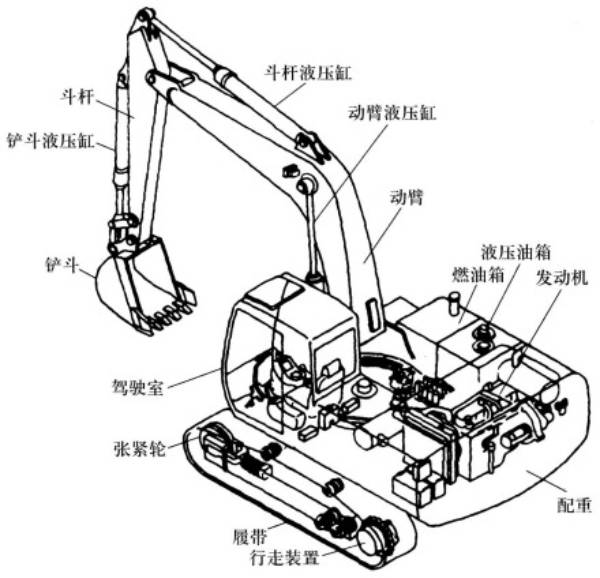

Structural composition

Common excavator structures include power units, working devices, slewing mechanisms, operating mechanisms, transmission mechanisms, walking mechanisms and auxiliary facilities.

The transmission mechanism transmits the power of the engine to the hydraulic motor, hydraulic cylinder and other actuators through the hydraulic pump, and pushes the working device to move, thereby completing various operations.

Walking device

The walking device is the chassis, including the crawler frame and the walking system, which is mainly composed of the crawler frame, the walking motor + reducer and its pipeline, the driving wheel, the guide wheel, the carrier wheel, the roller, the crawler, and the tensioning buffer device. The function is to support the weight of the excavator, and convert the power transmitted by the driving wheel into traction, so as to realize the walking of the whole machine.

The frame assembly (that is, the crawler walking frame assembly) is an integral welded part and adopts an X-shaped structure. Its main advantage is that it has a high bearing capacity. The frame assembly is welded by three parts: the left longitudinal beam (ie the left track frame), the main frame (ie the middle frame) and the right longitudinal beam (ie the right track frame). The weight of the frame assembly is 2 tons.

The central rotary joint is the hydraulic component connecting the rotary platform and the oil circuit of the chassis. It ensures that after the rotary platform rotates at any angle, the travel motor can still distribute oil normally. The current rotary joint is 5-way.

Classification

Common excavators are divided into two types: internal combustion engine-driven excavators and electric-driven excavators. Among them, electric excavators are mainly used in plateau hypoxia, underground mines and other flammable and explosive places.

According to different sizes, excavators can be divided into large excavators, medium excavators and small excavators.

According to different walking modes, excavators can be divided into crawler excavators and wheeled excavators.

According to the different transmission modes, excavators can be divided into hydraulic excavators and mechanical excavators. Mechanical excavators are mainly used in some large mines.

According to the use, excavators can be divided into different categories such as general excavators, mining excavators, marine excavators, and special excavators.

According to the bucket, excavators can be divided into front shovel, backhoe, dragline and grab shovel. Front shovels are mostly used to excavate materials above the surface, and backhoes are mostly used to excavate materials below the surface.

1. backhoe excavator

The backhoe is the most common we’ve seen, a back-down, forced cut. It can be used for excavation below the shutdown working surface. The basic operation methods are: ditch end excavation, ditch side excavation, straight line excavation, curve excavation, maintaining a certain angle excavation, ultra-deep trench excavation and trench slope excavation.

2. Front shovel excavator

The shovel action form of a front shovel excavator. It is characterized by “forward and upward, forced soil cutting”. The front shovel has a large digging force and can excavate the soil above the stop surface. It is suitable for excavating dry foundation pits with a height of more than 2m, but up and down ramps must be set up. The bucket of the front shovel is larger than that of the backhoe excavator of the same equivalent, and it can excavate the first to third types of soil with a moisture content of not more than 27%, and cooperate with the dump truck to complete the entire excavation and transportation operation, and can also excavate Large dry foundation pits and mounds, etc. The excavation method of the front shovel is based on the difference between the excavation route and the relative position of the transport vehicle. There are two ways of digging and unloading: forward digging, side unloading; forward digging, reverse To unload soil.

3. Dragline excavator

Draglines are also called draglines. The characteristics of its excavation are: “backward and downward, cutting the soil under its own weight”. It is suitable for excavation of Class I and II soils below the stop surface. When working, the bucket is thrown out by inertial force, and the digging distance is relatively large, and the digging radius and digging depth are large, but it is not as flexible and accurate as the backhoe. Especially suitable for excavating large and deep foundation pits or underwater excavation.

4. Grab and shovel excavator

Grab excavator is also called grab excavator. The characteristics of its excavation are: “straight up and down, cutting the soil under its own weight”. It is suitable for excavation of Class I and II soils below the stop surface, and is often used for excavation of foundation pits and caissons in soft soil areas. It is especially suitable for digging deep and narrow foundation pits, dredging old channels, digging up silt in water, etc., or for loading loose materials such as gravel and slag. There are two types of excavation: trench side excavation and positioning excavation. If the grab is made into a grid, it can also be used for loading ore blocks, wood chips, wood, etc. in the log yard.

The vast majority of today’s excavators are fully hydraulic azimuth excavators. Hydraulic excavators are mainly composed of engine, hydraulic system, working device, traveling device and electrical control. The hydraulic system consists of hydraulic pump, control valve, hydraulic cylinder, hydraulic motor, pipeline, fuel tank, etc. The electrical control system includes monitoring panel, engine control system, pump control system, various sensors, solenoid valves, etc.

Jiangsu Xingzhi Technology Co.,ltd provide Excavator Simulators.The Excavator Simulators are comprehensive training solution that provides an efficient way to learn and practice machine operation skills.The trainees could be trained in a targeted manner to operate various excavator types effectively in wide range of scenarios and environment.Through repetitious practice and the adequate preparation for the operation on the real machine,so as to reduce the repetitive errors and the accident rate of the potential dangerous operation.

Post time: Jun-13-2022